When it comes to cleaning pump parts, understanding the right methods and frequency is vital for maintaining efficiency. You might wonder how often you should clean your components or which solutions are safe to use. Common mistakes can lead to contamination or damage, so it’s essential to know what to avoid. Knowing how to prevent such issues can save you time and money. Let’s explore these important considerations further.

What Are the Best Cleaning Methods for Pump Parts?

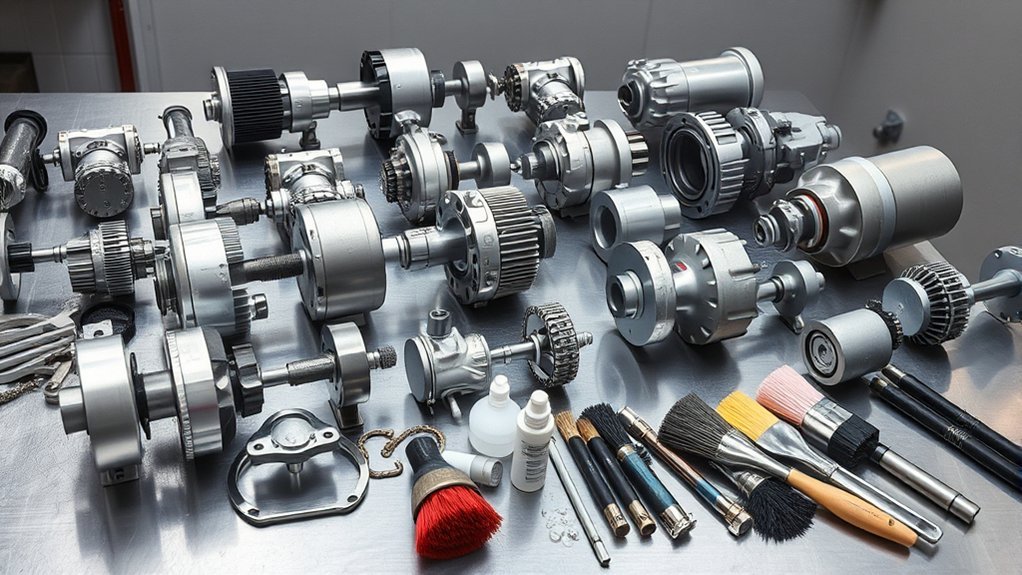

When it comes to maintaining pump efficiency, selecting the right cleaning methods for pump parts is essential. Start with a thorough rinse using water to remove loose debris.

For stubborn residues, consider using a mild detergent or a specialized pump cleaner, guaranteeing compatibility with the pump material. Ultrasonic cleaning is highly effective for intricate components, as it removes contaminants without abrasive damage.

For metal parts, abrasive cleaning techniques like sandblasting can be employed, but use caution to avoid surface damage. Always follow manufacturer guidelines and safety protocols during cleaning.

After cleaning, inspect all parts for wear or damage before reassembly, as this guarantees peak performance and longevity of the pump system.

How Often Should I Clean My Pump Components?

How frequently should you clean your pump components? The answer depends on your specific application and the type of fluid being pumped.

Generally, for standard operations, you should clean your pump parts every 30 to 90 days. If you’re working with abrasive or corrosive materials, consider cleaning them more frequently—possibly every two weeks.

For standard operations, clean your pump components every 30 to 90 days, or every two weeks for abrasive materials.

Monitor for signs of wear, buildup, or decreased efficiency, as these indicate the need for immediate cleaning. After any maintenance or repair, always clean the components before reassembly to guarantee ideal performance.

Additionally, keep a maintenance log to track cleaning intervals and conditions, which can help you enhance your cleaning schedule over time.

Regular maintenance improves longevity and reliability, guaranteeing your pump operates smoothly.

What Cleaning Solutions Are Safe to Use?

After establishing a regular cleaning schedule for your pump components, selecting the right cleaning solutions becomes crucial.

Use biodegradable detergents specifically formulated for industrial equipment. These solutions effectively remove grease, grime, and contaminants without damaging materials like rubber or metal.

Avoid harsh solvents or bleach, as they can corrode parts and leave harmful residues. Consider using vinegar or a baking soda solution for less stubborn stains; they’re safe and environmentally friendly.

Always refer to the manufacturer’s recommendations for cleaning agents compatible with your pump’s materials. Additionally, test any new cleaner on a small area first to confirm it won’t cause damage.

Proper selection of cleaning solutions helps maintain your pump’s performance and extends its lifespan.

What Common Mistakes Should I Avoid When Cleaning?

While cleaning pump parts, it’s easy to overlook key practices that can lead to damage or inefficiency. One common mistake is using abrasive materials, which can scratch or wear down surfaces. Always opt for soft cloths or non-scratching brushes.

Another pitfall is neglecting to fully disassemble the pump; residue can hide in hard-to-reach areas, compromising performance. Additionally, using the wrong cleaning solution can corrode components; always verify compatibility.

Be cautious with drying methods, too—using heat can warp plastic parts. Finally, rushing the process might lead you to miss critical inspection points, so take your time.

How Can I Prevent Contamination When Cleaning Pump Parts?

What steps can you take to prevent contamination when cleaning pump parts? First, make certain you’re using clean, dedicated tools and equipment. Avoid cross-contamination by keeping cleaning materials separate from those used for other tasks.

Follow these guidelines:

- Use appropriate cleaning agents specifically designed for pump materials.

- Implement a clean workspace free from dust and debris.

- Wear gloves and masks to prevent introducing contaminants from your skin or breath.

- Rinse components thoroughly to remove any residual cleaning agents or particles.

Frequently Asked Questions

Can I Use a Pressure Washer to Clean Pump Parts?

Yes, you can use a pressure washer to clean pump parts, but make sure you maintain a safe distance and use appropriate pressure settings. High pressure can damage components if applied too close or excessively.

What Protective Gear Should I Wear While Cleaning?

When cleaning, you should wear goggles, gloves, and a mask. It’s like battling a chemical monster; your gear’s your armor. Don’t underestimate the importance of protection—safety’s paramount in this hazardous endeavor!

How Should I Store Cleaned Pump Parts?

Store cleaned pump parts in a dry, dust-free area, preferably in labeled containers. Make sure they’re completely dry to prevent corrosion, and avoid stacking them directly on top of one another to prevent damage.

Are There Specific Cleaning Techniques for Different Pump Types?

Yes, different pump types require specific cleaning techniques. For instance, centrifugal pumps often need a gentle detergent solution, while diaphragm pumps may benefit from a vinegar rinse. Always follow manufacturer guidelines for best results and safety.

What Signs Indicate My Pump Parts Need Immediate Cleaning?

If you notice decreased performance, unusual noises, or visible residue buildup, your pump parts likely need immediate cleaning. Addressing these signs promptly can prevent further damage and guarantee efficient operation of your pump system.

Conclusion

In summary, regular cleaning of pump parts is essential for efficient operation, with a recommended frequency of every 30 to 90 days. Notably, studies show that proper maintenance can extend the lifespan of pump components by up to 50%. By choosing safe cleaning methods and avoiding harsh chemicals, you not only preserve the integrity of your equipment but also enhance performance. Stay diligent with your cleaning schedule and documentation to guarantee peak functionality and reduce unexpected downtime.